ball mill steel balls

Diameter:20-150mm(+2mm/-1mm tolerance)

Certificates:ISO 9001:2000, ISO 9001:2008, ISO9001, ISO14001, ISO18001

Customized: Customizable

Hardness: HRC60-65(forged steel ball), 45HRC-58HRC(casting steel ball)

Breakage rate: 1%max in normal and correct operating conditions.

Production capacity:150, 000 Mt/Year

Application: Mine, Cement, Electric Power Plant

Packaging: Steel Drum or Steel Barrel, Container Bag

Ball mill steel balls work as a ball mill equipment grinding material medium, through the ball mill between the steel ball and the friction between the ball and material grinding effect, important basic parts, especially precision industrial steel ball plays a huge role in the development of the national economy. Ball mill steel balls are widely used in cement plants, power plants and so on.

In the field of ball mill steel balls, there are two kinds of steel balls running in the ball mill or semi-automatic mill, one is forged steel ball, and the other is casting steel ball.

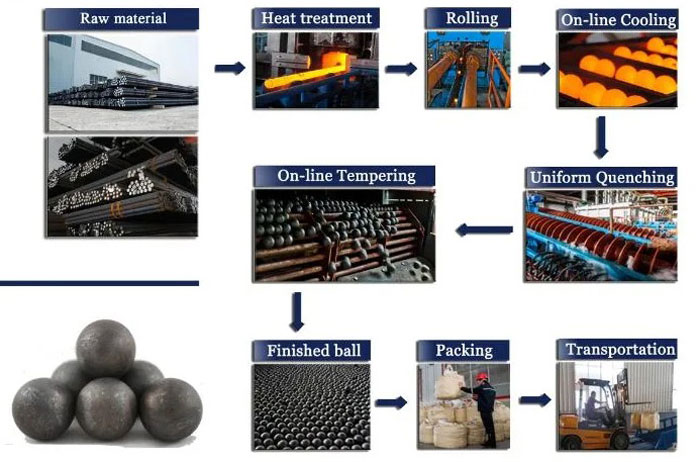

Forged steel ball

The forged steel ball is directly heated at high temperature and then forged by air hammer and other equipment. After simple heat treatment, the chromium content is 0.1% ~ 0.5%, and the carbon content is less than 1.0%. After high-temperature forging, the surface hardness (HRC) can reach more than 56, but due to poor hardenability of the material, the quenched layer is only about 15㎜, Therefore, the hardness of the core is generally only more than 30 degrees, and the larger the diameter of the forged steel ball, the worse the hardenability. Therefore, under normal circumstances, the forged steel ball is treated with water quenching.

Advantages of forged steel ball

1. Low crushing rate, reasonable alloying element ratio, stable overall performance, little gas and not easy to appear cavity, strict quenching process control, suitable for high yield, large mill use effect is obvious;

2. Uniform hardness (core table gap 1-2HRC) good performance, low loss of round rate, high wear resistance;

3. Good roundness, no appearance defects;

4. The specific gravity is slightly larger than the casting ball, impact crushing, shear force is large, improve the output obviously, but has little impact on the mill liner;

5. Compact organization, high-cost performance and obvious cost saving;

6. Environmental protection, do not pollute water.

Chemical elements(%)

C: 0.48-0.85, Si: 0.15-0.37, Mn: 0.7-1.0, P: 0.035 MAX, S: 0.035 MAX

| Nominal Diameter(mm) | Dimensional Tolerance(mm) | Roundness% |

|---|---|---|

| Φ20 | ±2 | ≤6 |

| Φ25 | ±2 | ≤6 |

| Φ30 | ±2 | ≤5 |

| Φ35 | ±2 | ≤5 |

| Φ40 | ±2 | ≤5 |

| Φ50 | +3,-1 | ≤4 |

| Φ60 | +3,-1 | ≤4 |

| Φ70 | +3,-1 | ≤4 |

| Φ80 | +3,-1 | ≤4 |

| Φ90 | +4,-2 | ≤4 |

| Φ100 | +4,-2 | ≤4 |

| Φ120 | +4,-2 | ≤4 |

| Φ125 | +4,-2 | ≤4 |

| Φ130 | +4,-2 | ≤4 |

| Φ140 | +4,-2 | ≤4 |

| Φ150 | +4,-2 | ≤4 |

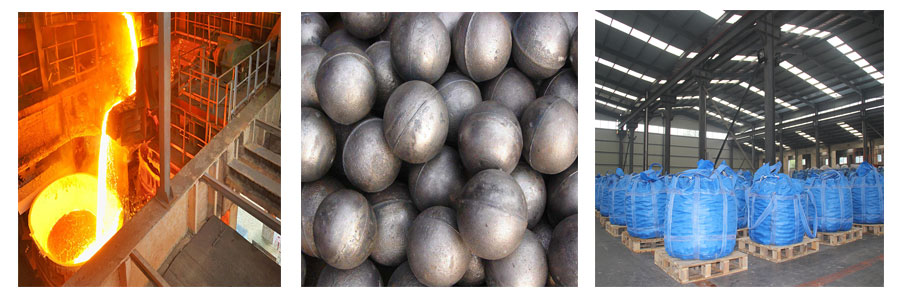

Casting steel ball

Casting steel ball is the steel ball that manufacturer will scrap steel, scrap iron and other waste furnace charge heating medium frequency electric furnace, so that the charge is fully melted, in the furnace charge melting process appropriate amount of precious metal alloy (such as ferrochrome, ferromanganese, iron vanadium, iron-nickel, electrolytic copper, etc.) to the furnace chemical composition quenching and tempering, After the hot metal temperature meets the requirements of the process, the qualified hot metal will be out of the oven, slag gathering, slag scraping, inoculation, deoxidation, static pouring into the steel ball mold or the steel ball production line mold. That is, the steel ball produced by the casting smelting method is called casting steel ball, which can be divided into three categories high chromium balls, medium chromium balls and low chromium balls.

Chemical elements

| Spec Available(%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Name | C | Si | Mn | Cr | Mo | Cu | P | S |

| Special High Chrome Alloyed Balls | 2.0-3.3 | ≤1.0 | 0.3-1.5 | 14-23 | 0-3.0 | 0-1.2 | ≤0.06 | ≤0.06 |

| High Chrome Alloyed Balls | 2.0-3.3 | ≤1.0 | 0.3-1.5 | 10-14 | 0-3.0 | 0-.12 | ≤0.06 | ≤0.06 |

| Medium Chrome Alloyed Balls | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 4-6 | 0-1.0 | 0-1.2 | ≤0.06 | ≤0.06 |

| Low Chrome Alloyed Balls | 2.1-3.6 | ≤1.5 | 0.3-1.5 | 1-3 | 0-1.0 | 0-0.8 | ≤0.06 | ≤0.06 |

Specification of casting steel ball

| Size(mm) | Weight(kg/pc) | Quantity(pc/t) |

|---|---|---|

| Φ30 | 0.11 | 9091 |

| Φ40 | 0.25 | 3891 |

| Φ50 | 0.50 | 2000 |

| Φ60 | 0.86 | 1153 |

| Φ70 | 1.37 | 729 |

| Φ80 | 2.05 | 487 |

| Φ90 | 2.90 | 345 |

| Φ100 | 4.00 | 250 |

| Φ110 | 5.30 | 188 |

| Φ120 | 6.80 | 147 |

| Φ130 | 7.70 | 129 |

| Φ140 | 8.74 | 114 |