tip plate and sealing parts

Rotary kiln inlet tip plate

Rotary kiln inlet tip plate is one of the kiln head components of the rotary kiln. Its main function is to fully protect the kiln inlet and outlet cylinder from burning, corrosion and deformation, and to protect and prolong the service life of the kiln inlet and outlet. To a certain extent, it is also a key factor for the stable operation of the rotary kiln.

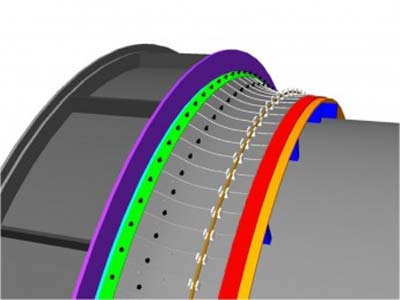

Rotary kiln inlet tip plate, generally made of high-chromium heat-resistant steel, has a T-shaped flat structure, and several dense mouth guard plates are respectively installed on the kiln inlet and outlet through bolts to form a closed circle. The working face of the kiln inlet and outlet tip plate is built with a protective layer of refractory castables, so as to achieve the purpose of protecting the kiln inlet and outlet. The rotary kiln inlet tip plates are distributed in a fan shape at the kiln mouth. Considering the thermal expansion factor, a radial expansion gap must be set between two adjacent rotary kiln inlet tip plates to prevent the heat from squeezing each other and causing damage.

Rotary kiln sealing system

Rotary kiln sealing system is an auxiliary equipment of rotary kiln and dryer. It is widely used in building materials, metallurgy, chemical industry, cement, petroleum, mining and other industries. It is not a single sealing form, but has many types. Cement rotary kiln is a thermal equipment that operates under negative pressure. The sealing condition of both ends of the cement clinker is directly related to the output, quality and energy consumption of the clinker. Due to the extreme load on both sides of the rotary kiln, not only the temperature is high, but also rotation and shaking exist at the same time, so the rotary kiln sealing system is both important and difficult. Strengthening and improving the rotary kiln sealing system is one of the important ways for rotary kiln cement plants to increase production and save energy.

Lamella seal

Lamella seal is a form of seal with a shape similar to fish scale. The characteristics of high temperature resistance and non-wearing make it widely used in industry.

One of the sealing forms of rotary kiln is lamella, which is also the current mainstream sealing form. It is simple to maintain and install, and has tightness. It can be used in both the kiln inlet and the kiln outlet of the rotary kiln.

Lamella seal is made of special high-temperature and wear-resistant double-flexible heat-resistant steel, with advantages of no air leakage, no ash leakage, no material leakage, high temperature resistance, wear resistance, long life, high performance, easy installation, and low cost of use. It is also widely used in dryers and single-cylinder coolers, which is a common sealing form. Taking the cement industry as an example, the rotary kiln head sealing adopts lamella seal, and the proportion of lamella seal used for the kiln tail sealing is also relatively large.

Graphite block sealing

Rotary kiln graphite block sealing is square graphite for cement rotary kiln. Rotary kiln graphite block graphite plate has good characteristics such as good electrical conductivity, high temperature resistance, acid resistance, alkali corrosion resistance and easy processing. Graphite is used as sealing and lubricating material in many cement rotary kilns. Rotary kiln graphite block sealing is generally used to seal the kiln head and kiln tail, and can also be used for lubrication between the support wheel and the belt. Graphite blocks have necessary heat resistance and excellent self-lubricating properties, and can well consider the regulations of rotary kiln sealing, so they are more commonly used in rotary kilns.