crusher frame

Crusher Frame

Weight: 5-50T

Application: Mining, cement, chemical and other industries

Material: ZG270-500 steel

Customizable: Yes

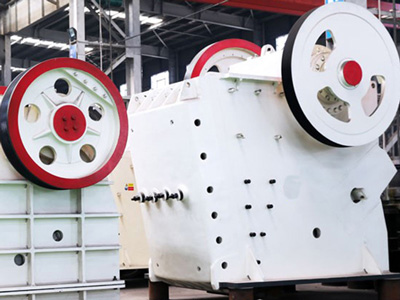

The crusher frame is the skeleton structure of large crushers such as cone crushers and jaw crushers, supporting all the working parts of the equipment, and its structural design has a greater impact on production. The crusher frame is a four-wall rigid frame with upper and lower openings, which is used to support the eccentric shaft and bear the reaction force of the crushed material. Small-capacity jaw crushers can also use good cast iron to replace cast steel. Large-capacity jaw crushers need to be cast in sections, and then reinforced with screws to form a whole. The casting technology is complicated.

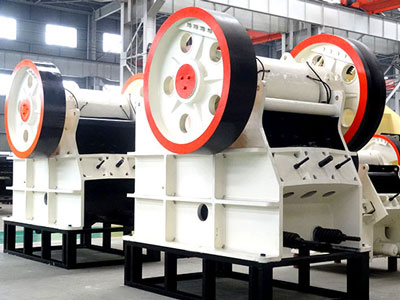

Jaw Crusher This series of products adopts cast steel crusher frame and movable jaw, with high strength and long service life. It has the characteristics of large crushing ratio, uniform product particle size, simple structure, reliable operation, easy maintenance and low operating cost.

The reason for the cracking of the crusher frame

1. The movable jaw and fixed jaw of the crusher continue to be used after the tooth shape is worn, and they are not repaired in time.

2. During production, the quality problems of the equipment itself caused by insufficient casting technology or welding.

3. The fixing of the fixed jaw plate is not strong enough, and the crusher works in a continuous vibration state for a long time, which causes the fixed jaw to become loose and hits the front wall of the crusher frame, causing damage to the frame.

4. The bolts of the crusher frame bearing are not tightened during installation, and there is a loose phenomenon.

5. The rigidity of the base of the main machine is out of tolerance or collapsed, causing the crusher frame to jump;

6. The direction of the flywheel counterweight is dislocated due to damage to the eccentric shaft, pin or loose expansion sleeve.

7. The selection of brackets and bracket pads is unqualified and cannot withstand huge impact force. When the crusher is subjected to strong impact, it cannot play the role of buffering and self-protection, resulting in damage or breakage of the crusher frame.

Advantages of AGICO Cement’s Crusher Frame

1. AGICO Cement can produce various types of crusher frame, cone crusher, impact crusher, jaw crusher and other crusher frame casting, and can also be tailored for enterprises according to drawings.

2. High-strength steel is used and optimized for the operating characteristics of the crusher, which greatly enhances the impact resistance and wear resistance of the crusher frame and prolongs the service life.

3. A complete set of product solutions can be provided to meet the professional and personalized product needs of customers.

4. Professional flaw detection equipment testing, so that product quality can be guaranteed.

5. High hardness, good crack resistance, and fine workmanship.

.jpg)