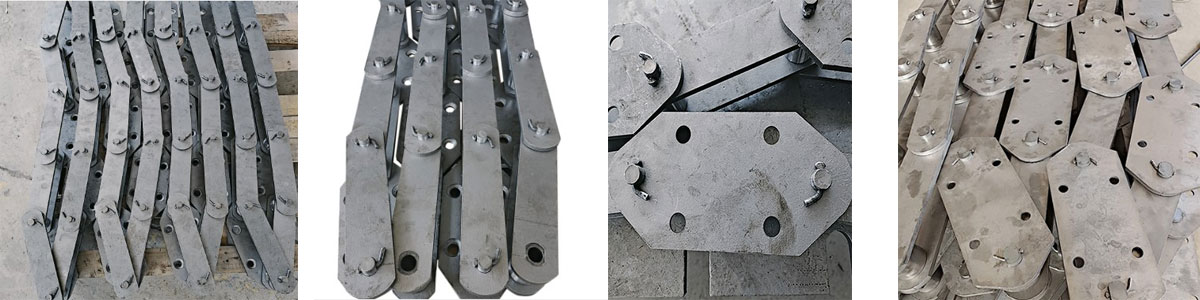

plate chain and circle chain

Bucket elevator plate chain

AGICO plate chain is mostly used for cement raw meal, clinker elevator, and can also be used for coal and stone materials with high abrasiveness. Customizable plate chain is suitable for various kinds of bucket elevator. It is a high-strength chain processed by heat treatment of alloy steel. Under normal continuous use, the service life of the conveyor chain is guaranteed to be 3-5 years . The running part on the plate chain type for bucket elevator, the hopper is mounted on it, which is used to lift the material from a low place to a high place for unloading. The plate chain has good sealing performance and less ring gold pollution. Easy to operate and maintain, less wearing parts. The use cost is low, and the use cost of the leaf chain is extremely low due to energy saving and less maintenance. Reliable operation, the mechanical size of this leaf chain is small. Large conveying capacity, plate chain is an important transportation equipment in coal mine production, and plays a vital role in the safety of the entire working face.

Installation of plate chain of bucket elevator

The machine parts in the structure of the elevator chain are assembled into one by the upper casing, the driving shaft parts, the reducer, the coupling, the motor, etc. According to the height required to be lifted and the different number of middle casings, the central casing can meet the needs. The bucket elevator chain of AGICO Cement is composed of round steel welded ring chains. The hopper is vibrated on the joint of the chain with a nut. Bucket elevators with different heights are now equipped with corresponding number of chains, joints, and hoppers. Mechanical part: main shaft device, reducer, coupling, brake, hydraulic station, depth indicator and its transmission device, tachometer speed device, guard plate, guard cover, guardrail. The main parts of the bucket elevatoring head wheel and the bottom wheel bearing rotation of the tail wheel are the high-quality alloy steel high-strength plate chain, which is wear-resistant and reliable. The drive part adopts a hard tooth surface reducer.

Advantage of our plate chain for bucket elevator

1. Select high-quality raw materials. Stainless steel has the characteristics of not easy to rust, high strength and toughness, and is suitable for harsh environments such as humidity.

2. Stable performance. The surface of the product is smooth, and each solder joint has a stable bearing capacity.

3. Reasonable structure. Chains can enter and exit engagement smoothly, reducing impact and contact stress on the links during engagement.

4. Reduce consumption. Realize the filling, lifting and unloading of materials. Reduce production capacity and reduce useless consumption in the process.

Bucket elevator circle chain

The bucket elevator circle chain is generally a high-quality 40CR high-strength chain, which is wear-resistant and reliable. AGICO Cement provides customized service for its circle chain for bucket elevator.

Circle chain of bucket elevator adopts mixed or gravity unloading and digging type loading. Alloy steel height circle chain for traction parts. The central casing is divided into single and double channel forms for the constant force and automatic tension of the weight box in the machine. The bucket elevator adopts a combined structure of replaceable rims. Long service life and easy rim replacement. The lower part adopts gravity automatic tensioning device, which can maintain a constant tensioning force and avoid slipping or de-chaining. At the same time, the hopper has a certain tolerance when it encounters the jam phenomenon caused by accidental factors, which can effectively protect the lower shaft and other components. The TH315 circle chain bucket elevator is suitable for conveying powdery, granular and small block bottom grinding materials with bulk density less than 1.5t/m3. Such as coal, cement, gravel, sand, fertilizer, grain, etc.

Advantage of circle chain for bucket elevator

1. Deep hardening. After hot forging, it is strong and not easy to break, and the surface is polished and black, and the interface is smooth

2. Welding process. Strict selection of chain raw materials, control of production quality, firm welding and long use time