gear reduction box

Benefits of AGICO Cement's gear reduction box

1. Space-saving, reliable and durable, high overload capacity;

2. Low energy consumption, superior performance, gear reduction box efficiency of more than 95%;

3. Low vibration, low noise, high energy saving;

4. Select high-quality forged steel materials, rigid cast iron box, gear surface after high-frequency heat treatment;

5. After precision machining, ensure the parallelism of the shaft and the positioning bearing requirements, the gear reduction box with helical gear transmission assembly is equipped with various types of motors, combined into mechatronics, and completely optimizes the product quality characteristics.

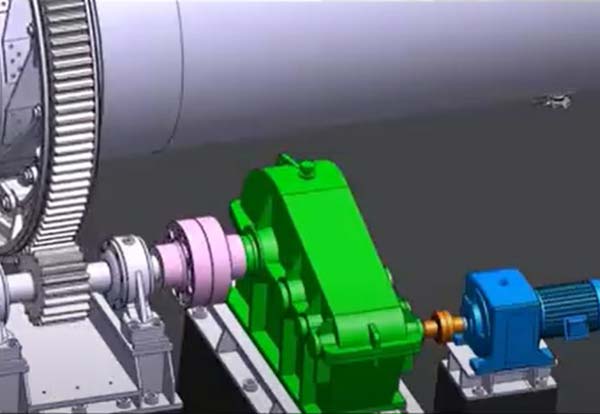

Brief introduction of reduction box

The rotary kiln gear reduction box is usually used in rotary kiln equipment in the chemical industry, environmental protection industry, raw materials and mining industry, pulp and paper industry, steel industry, cement industry and other industries. Its main function is to convert the high-speed rotation of the motor into the low-speed rotation required by the rotary kiln through the reduction device to ensure the stable operation of the equipment. Here are some key features of the rotary kiln gear reduction box:

High load-bearing capacity: Rotary kiln equipment is usually large and heavy, so the gear reduction box needs to have a very high load-bearing capacity to cope with the load of the rotary kiln.

Efficient transmission: The gear reduction box needs to have an efficient transmission ratio to ensure that the power of the motor can be effectively transmitted to the drive system of the rotary kiln.

Long lifespan: Since rotary kilns usually need to run continuously for a long time, the design of the gear reduction box needs to have good durability and reliability.

Low noise: In order to reduce noise pollution in industrial production, the design of the gear reduction box usually considers the requirement of low noise.

Easy maintenance: Since the working environment of rotary kiln equipment is usually harsh, the design of the gear reduction box needs to consider the convenience of maintenance to reduce downtime and maintenance costs.

AGICO Cement also provides other spare parts for rotary kiln such as kiln tyre, kiln support roller, kiln shell, tip plate and sealing parts, bearing bush.

Working principle of gear reduction box

Power input

The gear reduction box receives power input from the motor. The motor generates power through its rotational motion, and this power is transmitted to the gear reduction box through devices such as couplings.

Speed reduction and torque increase

The gear reduction box converts the high-speed and low-torque rotation of the motor into low-speed and high-torque rotation through a series of gear meshing (such as helical gears, spur gears, planetary gears, etc.). In this process, the gear ratio determines the speed reduction ratio of the gear reduction box, that is, the ratio of the output speed to the input speed.

Power output

The power after speed reduction and torque increase is transmitted to the transmission device of the rotary kiln (such as large ring gear, small gear, etc.) through the output shaft of the gear reduction box, thereby driving the rotary kiln to rotate slowly.

Gear reduction box types and how to choose

Cylindrical gear reduction gearbox for sale

Features: It adopts multi-stage cylindrical gear transmission, with high transmission efficiency and compact structure.

Application: It is suitable for medium loads and occasions requiring high transmission efficiency.

Planetary gear gear reduction box:

Features: It has a compact structure, light weight, and strong load-bearing capacity, especially suitable for applications with limited space but high load capacity.

Application: It is often used in rotary kiln systems that require high precision and high load.

Worm reduction gearbox for sale:

Features: It has a self-locking function, which can prevent the rotary kiln from reversing when it stops, with a large transmission ratio and low noise.

Application: It is suitable for occasions that require a large transmission ratio and self-locking function, but the efficiency is relatively low.

Get free quote of gear reduction box

Cycloidal pinwheel reduction gearbox for sale:

Features: Smooth transmission, low vibration, compact structure, and high impact resistance.

Application: It is suitable for rotary kiln equipment that requires high durability and low noise.

Helical gear reduction gearbox for sale:

Features: The helical gear design provides higher transmission efficiency and lower noise, suitable for high torque applications.

Application: It is commonly used in large rotary kiln systems, especially those that require high efficiency and low noise.

Multi-stage combination reduction gearbox for sale:

Features: Combine the above multiple gear reduction box forms to meet specific transmission requirements, such as a larger transmission ratio or higher load capacity.

Application: It is suitable for very large or special rotary kiln equipment.

Coaxial gear reduction box:

The input shaft and output shaft of the coaxial gear reduction box are located on the same axis, with a compact structure and a small footprint. In the rotary kiln industry, coaxial gear reduction boxes are often used in space-constrained occasions.

Parallel shaft gear reduction box:

The input shaft and output shaft of the parallel shaft gear reduction box are arranged in parallel, which is suitable for a variety of transmission methods. In the rotary kiln industry, the parallel shaft gear reduction box can be flexibly configured according to specific needs.

Best reduction box from reliable gear reducer manufacturer

- Made of high-strength alloy materials, it has strong load-bearing capacity and wear resistance. Its main components include cylindrical gears, gear shafts, housings, etc., which are precision machined and heat-treated to ensure the stability and reliability of the gear reduction box.

- At the same time, the reduction box also adopts an optimized gear transmission structure, which makes the transmission efficiency as high as more than 96%, reducing energy waste. In addition, AGICO Cement's reduction box also has an automatic lubrication function, which can effectively extend the service life.

- The reduction box also has the characteristics of low noise, low vibration and low energy consumption, providing users with a comfortable working environment.

- As a gear reducer manufacturer, AGICO Cement produces reduction boxes that are strictly inspected in every process, with precise parameters. After assembly, they are strictly inspected for temperature rise, vibration, noise, and high pass rate. They are also tested and run. All products are free of oil leakage, with excellent overall performance, excellent product quality, fair price, and complete after-sales service.

Contact us to learn all models of reduction box

How to use reduction gearbox for sale in a correct way?

The reduction box of rotary kiln owner is one of the core equipment of rotary kiln, and its operation execution standard is directly related to the production efficiency and safety of the entire kiln. Therefore, before operating the gear reduction box of rotary kiln owner, it is necessary to understand its operation execution standard.

Operation Execution Standards

1. Inspection: Before the gear reduction box of the rotary kiln is operated, the gear reduction box should be fully inspected to check the working condition of the gear reduction box and the damage of the accessories, etc., to ensure the normal operation of the gear reduction box.

2. Cleaning: After the inspection is completed, the gear reduction box should be cleaned to remove the oil on the surface of the gear reduction box and the dirt inside the gear reduction box, etc., to ensure that the surface of the gear reduction box is clean and there are no impurities inside.

3. Lubrication: When the gear reduction box of the rotary kiln is operated, it should be ensured that the lubricating oil in the gear reduction box is sufficient, the oil temperature should meet the standard requirements, and sufficient lubrication and maintenance should be carried out.

4. Installation: When installing the gear reduction box, it should be strictly operated according to the installation instructions of the gear reduction box to avoid installation errors.

5. Debugging: After the gear reduction box is installed, it should be debugged to check whether the working condition of the gear reduction box is normal. If there is any abnormality, the accessories should be replaced in time.