kiln support roller

Product: Kiln support roller/support roller for rotary kiln

Material: ZG55, ZG42CrMo, etc,

Weight: 7-42 T

Application: Rotary kiln, rotary dryer, rotary cooler, etc.

Customizable: yes

Certificate: ISO9001:2015

Production Capability: 50000 Ton/Tons per year

Packaging Details: Standard package

Introduction

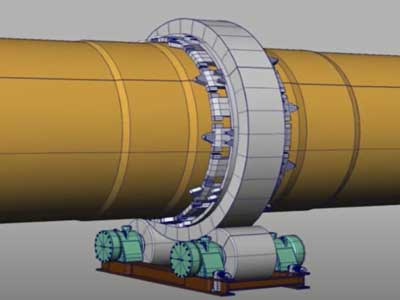

The kiln support roller is the main load-bearing equipment on the rotary kiln. The supporting roller device bears the weight of the entire rotary kiln (mainly cylinder, lining brick, heat exchange device in the kiln, material, rolling ring, gear ring) so that the cylinder and the rolling ring can rotate smoothly on the kiln support roller. The weight of a set of rotary kiln equipment in normal operation is about 100 tons. Such heavy equipment relies on the kiln support roller to support the operation result in the durability becoming one of the standards for measuring the good quality of rotary kiln support roller.

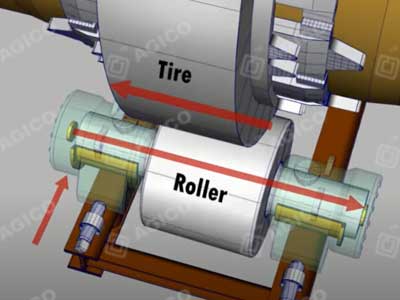

The complete supporting roller device consists of a large bear, two front and rear gears on the base, and each gear is equipped with two supporting rollers and four bearings and other components. The rollers indirectly support the drum through the belt, and the rollers also play the role of fixing the position of the drum while the drum rotates, so that the drum does not swing back and forth. The kiln support roller with strong pressure resistance and high wear resistance can ensure the efficient, continuous and stable operation of the rotary kiln for a long time.

The front and rear supporting roller sets of the rotary kiln mainly bear the full weight of the kiln cylinder, and play a role in positioning and limiting the kiln cylinder, so that it can run safely and smoothly. The front and rear supporting roller sets of AGICO are self-aligning rolling bearing structures, which are compact in structure, light in weight, and equipped with water-cooling devices to reduce the bearing temperature with reliable operation and strong adaptability.

Advantages of AGICO support roller for rotary kiln

1. High quality support roller for rotary kiln with high load and well performance

The support roller for rotary kiln produced by AGICO are generally made of ZG55, ZG42CrMo and other superior steel. On the one hand, the material ensures the quality of the support roller for rotary kiln, on the other hand, it also has the features of large-load bearing and good continuous operation;

2. Simple structure, easy to adjust and maintain

AGICO's support roller for rotary kiln adopts rolling bearing wheel set which has the characteristics of simple structure and convenient maintenance;

3. Normalizing and tempering technology endows product with high hardness

AGICO adopts the process of normalizing and tempering in the casting of the support roller for rotary kiln to increase the surface hardness of the outer circle of the supporting roller higher than 200HB, which ensures the quality of the support roller for rotary kiln;

4. Mature technology and short delivery time

A technical team of well-known domestic foundry manufacturers organized by AGICO is responsible for the company's technology, process, management and operation, and has established a scientific and sound technology, production and operation management system to effectively ensure the product quality and product quality and delivery date required by customers;

5. Strict factory inspection to ensure standardized quality

Each batch of AGICO products must undergo professional inspection by professionals before leaving the factory. From small to large, each product must meet the national standards before it is allowed to leave the factory, and a product qualification certificate is attached.