Rotary Airlock Valve

Rotary Airlock Valve Overview

A rotary airlock valve (also known as a rotary valve) serves two main functions: ensuring smooth and consistent material flow and providing an airtight seal. It is typically installed between the discharge pipe of an upper cyclone and the inlet of a heat exchange pipeline leading to a lower cyclone. The design of the rotary airlock valve must be reasonable, lightweight, and flexible.

Product that fullfill structural requirements for rotary airlock valves

1. Durability and Heat Resistance: The valve body and internal components should be sturdy and resistant to heat, preventing deformation or damage from overheating.

2. Smooth Operation: The valve plate should swing lightly and flexibly, with the counterweight easily adjustable to prevent excessive movement. The material flow should be even, often achieved by having round or arc-shaped holes at the front end of the valve plate.

3. Airtightness: The valve body must be airtight, with the valve plate fitting snugly against the pipe's inner wall. Any potential leaks through connection flanges or bearing gaps must be eliminated.

4. Bearing Protection: The bearings supporting the valve plate's shaft should be well-sealed to prevent dust from entering.

5. Ease of Maintenance: The valve body should be easy to inspect, disassemble, and maintain, with components that are easily replaceable.

AGICO CEMENT also provides other spare parts for big machinery, such as crush rotor, grind roller, slag pot and so on.

Introduction

In the pre-decomposition system of cement kilns, the primary function of the rotary airlock valve is to separate materials and prevent air flow short-circuiting. This valve plays a crucial role in energy conservation and reducing consumption. It is a commonly used discharge device for hoppers, featuring a simple structure and requiring no power. The valve automatically opens and closes under the weight of the material, using a counterweight lever system to reset the valve plate after the material has fallen. This design is widely used in industries such as building materials, metallurgy, chemicals, and cement.

Application Range

These valves are suitable for industries such as building materials, metallurgy, chemicals, and power, serving as ideal discharge devices for various dust collection equipment, mills, dryers, and silos.

AGICO CEMENT--Best choice of rotary airlock valve supplier

Rotary airlock valves are widely used in the cement industry, where increasing demands for automation, specialization, and green energy efficiency are raising the performance standards for these valves. Cement industry rotary airlock valves are typically used with preheaters and need to rotate around an axis. Therefore, they must have excellent self-actuation, heat and corrosion resistance, airtightness, and impact strength.

- Self-Actuation: The valve can automatically open and close using the weight of the material, ensuring short movement distances, high frequency, and even discharge.

- Heat and Corrosion Resistance: The valve's lining must resist high-temperature erosion from alkaline cement materials, ensuring a long service life.

- Airtightness: During discharge, the valve must prevent hot air from entering the discharge pipe and control dust, thereby maintaining discharge rates and improving the working environment.

- Impact Strength: The lining must resist external forces, especially during tests such as the brick-throwing test for checking foreign objects in the discharge pipe.

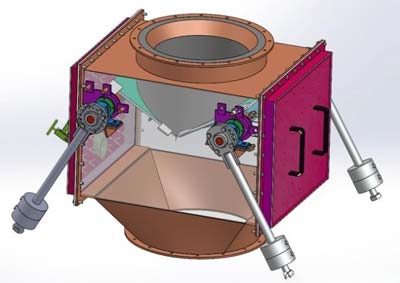

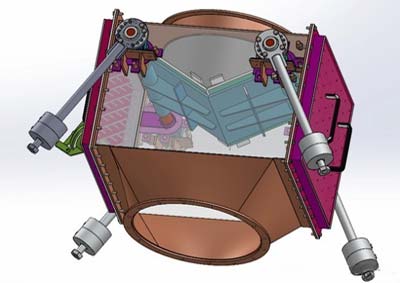

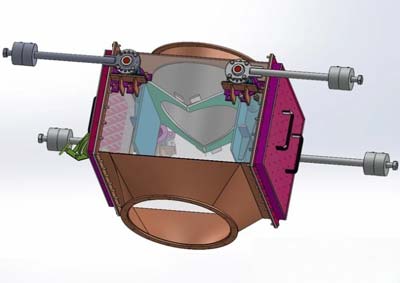

AGICO CEMENT's new-generation rotary airlock valve for clinker preheater systems is developed using advanced CFD (Computational Fluid Dynamics) numerical simulation technology and 3D design simulations. These valves feature excellent air locking, preventing internal leaks, airflow into the discharge pipe, and cross-winds, thereby improving heat exchange efficiency between materials and air and reducing thermal losses.

Product Types and Specifications

The new rotary airlock valves are classified into three types based on their application in preheater systems:

1.Symmetrical Double Rotary Airlock Valve: Used for vertical discharge pipes.

2.Asymmetrical Double Rotary Airlock Valve: For discharge pipes inclined at less than 45°.

3.Single Rotary Airlock Valve: For discharge pipes inclined at more than 45°.

These valves effectively solve various air leakage problems, reduce system thermal losses, and are recognized for their stability and economic benefits.

Product Features

Blockage Prevention: Engineered to prevent bridging and clogging.

Drive Options: Available in gravity, pneumatic, and electric drive mechanisms.

Simple Structure: Designed to provide excellent airtightness.

High-Temperature Resistance: Suitable for use in high-temperature environments.

Material Choices: Options include stainless steel (SS304, SS304L, SS316, SS316L) and carbon steel.

High Sealing Performance: Valve plates and seats alternate to maintain a tight seal.

Optional Flange Shapes: Available in both square and round configurations.

Specifications

| Model | Outer Diameter (mm) | Effective Inner Diameter (mm) | Total Height (mm) | Weight (kg) | Application Area |

| A-600 | 612 | 440 | 1200 | 600 | Vertical or inclined discharge pipes |

| A-700 | 712 | 500 | 1380 | 740 | Vertical or inclined discharge pipes |

| A-800 | 812 | 600 | 1550 | 870 | Vertical or inclined discharge pipes |

| A-900 | 912 | 700 | 1680 | 980 | Vertical or inclined discharge pipes |

| A-1000 | 1012 | 800 | 1750 | 1120 | Vertical or inclined discharge pipes |

| A-1100 | 1112 | 900 | 1820 | 1250 | Vertical or inclined discharge pipes |

| A-1200 | 1212 | 1000 | 1980 | 1400 | Vertical or inclined discharge pipes |

| B-600 | 612 | 440 | 900 | 800 | Vertical or pipes inclined <10° |

| B-700 | 712 | 500 | 1000 | 900 | Vertical or pipes inclined <10° |

| B-800 | 812 | 600 | 1100 | 1050 | Vertical or pipes inclined <10° |

| B-900 | 912 | 700 | 1200 | 1120 | Vertical or pipes inclined <10° |

| B-1000 | 1012 | 800 | 1300 | 1240 | Vertical or pipes inclined <10° |

| B-1100 | 1112 | 900 | 1400 | 1380 | Vertical or pipes inclined <10° |

| B-1200 | 1212 | 1000 | 1500 | 1550 | Vertical or pipes inclined <10° |

| C-600 | 612 | 440 | 1380 | 1000 | Pipes inclined <45° |

| C-700 | 712 | 500 | 1480 | 1050 | Pipes inclined <45° |

| C-800 | 812 | 600 | 1580 | 1120 | Pipes inclined <45° |

| C-900 | 912 | 700 | 1680 | 1240 | Pipes inclined <45° |

| C-1000 | 1012 | 800 | 1780 | 1380 | Pipes inclined <45° |

| C-1100 | 1112 | 900 | 1880 | 1500 | Pipes inclined <45° |

| C-1200 | 1212 | 1000 | 1980 | 1620 | Pipes inclined <45° |