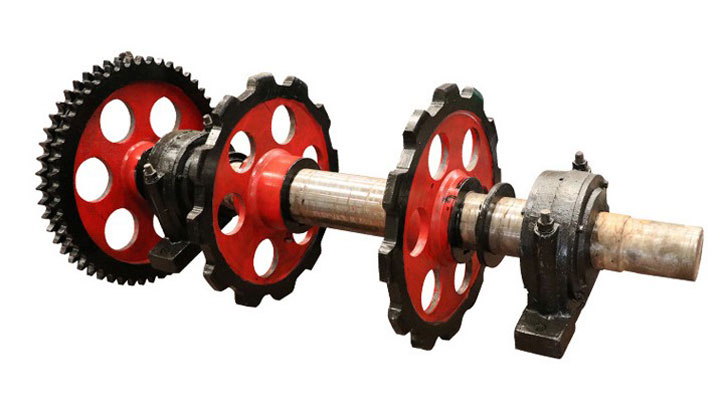

chain wheel

Chain Wheel for Bucket Elevator

A chain wheel is a wheel with cog-style chain wheel teeth that engages the exact pitch blocks on the link link or cable. chain wheels are widely used in chemical industry, textile machinery, escalators, wood processing, three-dimensional parking garages, agricultural machinery, food processing, instrumentation, mechanical transmission in petroleum and other industries.

The bucket elevator chain wheel is processed by multiple processes and made of 45# steel. The workmanship is fine, and every detail is strictly required. The tooth surface of chain wheel is heat treated and has the characteristics of high strength, strong performance and high precision. On the bucket elevatoring equipment used as transmission and conveying, chain scraper conveyor, bucket elevator, etc., and the tooth shape of the conveying chain wheel is different from the general transmission chain, and the pitch should be consistent with the conveying chain when selecting.

Customize Service

If there are drawings to provide drawings, or the model of the bucket elevator, the number of teeth, diameter of the chain wheel, and the size of the inner hole, the standard ones are available, and the non-standard ones can be customized according to the size provided by the customer.

There are standard models of head and tail wheels, non-standard customers need to provide drawings, or the width of the bucket elevator shell and the size of the bearing seat to process the customized shaft.

The tooth profile of the bucket elevator chain wheel should ensure that the chain can enter and exit meshing smoothly and freely, minimize the impact and contact stress of the chain link during meshing, and be easy to process. The chain wheel material should ensure that the teeth have sufficient strength and durability. , The chain wheel tooth surface is heat treated to ensure the hardness and durability of the chain wheel.

.jpg)

Daily maintenance and maintenance of chain wheel

1. The tightness of the chain wheel should be appropriate. If it is too tight, the power consumption will be increased, and the bearing will be easily worn; if the chain wheel is too loose, it will be easy to jump and fall off the chain. The tightness of the chain wheel is: lift or press down from the middle of the chain wheel, which is about 2%-3% of the distance between the two chain wheels.

2. There should be no swing and skew when the chain wheel is installed on the shaft. In the same transmission assembly, the end faces of the two chain wheels should be in the same plane. When the middle distance of the chain wheels is less than 0.5 meters, the deviation can be 1 mm; when the middle distance of the chain wheels is more than 0.5 meters, the deviation can be 2 mm. However, there should be no friction on the side of the chain wheel teeth. If the offset of the two wheels is too large, it will easily cause off-chain and accelerated wear. When changing chain wheels, pay attention to checking and adjusting the offset.

3. After the chain wheel is seriously worn, it should be replaced with a new chain wheel and a new chain wheel at the same time to ensure good meshing. You can't just put in a new chain wheel or a new chain wheel alone. Otherwise, it will cause poor meshing and accelerate the wear of the new chain wheel or the new chain wheel. After the chain wheel tooth surface is worn to a certain extent, it should be turned over and used in time (referring to the chain wheel used on the adjustable surface) to increase the use time.

4. If the new chain wheel is too long or stretched after use, it is difficult to adjust. The chain link can be removed according to the situation, but it must be an even number. The links should pass through the back of the chain wheel with the cleats inserted outside and the openings of the cleats should be facing the opposite direction of rotation.

5. The chain wheel should be filled with lubricating oil in time during work. The lubricating oil must enter the matching gap between the roller and the inner sleeve to improve the working conditions and reduce wear.

6. The old chain wheel cannot be mixed with some new chain wheels, otherwise it will easily cause shock during transmission and break the chain wheel.

7. When the machine is stored for a long time, the chain wheel should be removed and cleaned with diesel oil, then coated with oil or butter and stored in a dry place.