centrifugal blower

Centrifugal Blower for Grate Cooler

Material: Carbon steel, alloy, stainless steel, etc.

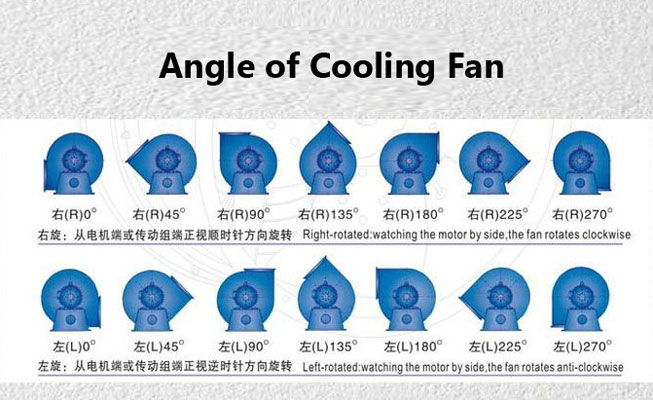

Customizable: Air volume, wind pressure, diameter of impeller, color, weight, number of leaves, rotation, airflow direction, fan pressure, etc.

The grate cooler is one of the important main equipments in the clinker firing system of the cement plant. Its main function is to rapidly cool and transport the cement clinker out of the rotary kiln, and at the same time provide hot air for the rotary kiln and the decomposition furnace. It is the main equipment for heat recovery of the system.

A grate cooler is a quench cooler. After the clinker enters the cooling machine from the kiln, a certain thickness of material layer is spread on the grate plate, and the bubbling cold air passes through the moving material layer on the grate bed in a mutually perpendicular direction to quench the clinker, which can be used in The clinker is quenched from 1300-1400 ℃ to below 100 ℃ in a few minutes. Generally, each grate cooler is equipped with 4~21 cooling fans. The process layout between the cooling fan and the grate cooler has two types: standard exhaust arrangement and circulating arrangement. Most industrial production adopts standard exhaust arrangement. The second-generation grate cooler, the third-generation air beam grate cooler and the fourth-generation grate cooler are widely used, and the technology is mature.

AGICO Cement provides grate cooler centrifugal blower, which are used for forced ventilation cooling of grate coolers, and can be matched with large-scale fan equipment for cement production lines with a daily output of 1,000 to 10,000 tons.

Features of AGICO Cement grate cooler centrifugal blower

1.High internal efficiency and wide high-efficiency area, which can greatly save power, 10--30% of power compared with other fans.

2. The performance curve is flat, the adjustment range is wide and the adjustability and controllability are ensured. When making adjustments, the vibration speed of the bearing housing is not obvious.

3. The advanced backward blade fan is selected, the motor is not easy to be overloaded, and the patented cylindrical bearing box is selected, which has a simple structure, reliable operation, convenient disassembly, assembly and maintenance.

4. The short flow detection device is adopted, which has high detection accuracy and reduces the floor space.

5. A new type of double-joint bearing axial adjustment door is adopted, which greatly reduces the static friction resistance torque, and the operation is stable and reliable. Supporting equipment: fan host integral bracket, motor, electric actuator, flow detection device, temperature measurement device, vibration monitoring device and muffler (configured according to usage)

Advantages of our centrifugal blower

1. High-efficiency aluminum-magnesium impeller (special for shaft seal oil tank fan)

2. High temperature and zero leakage (under 500 degrees)

3. High temperature corrosion resistance (using high-quality alloy stainless steel)

4. Super wear-resistant fan (wear-resistant manganese plate and wear-resistant ceramic fan)

5. Discreet gas fan (gas, shale gas, biogas, phosphorus powder, strong corrosive exhaust gas, etc.)

6. Stainless steel casting shaft disc, non-standard stainless steel castings.