torpedo Ladle

Introduction

The torpedo ladle is a large molten iron transportation equipment, which has the advantages of small heat loss, long holding time, energy saving, etc. It can also store molten iron to coordinate the temporary unbalanced state of ironmaking and steelmaking. It can also complete desulfurization, dephosphorization and other operating procedures during the transportation of molten iron.

Working process

Blast furnace tapping - torpedo ladle - pouring pot (folding pot) - molten iron pretreatment - converter (electric furnace) - refining - continuous casting (die casting) - casting billet (steel ingot) - storage inspection and repair Grinding - (slow cooling) - heating furnace - blooming, finishing - finishing - (heat treatment) - quality inspection - delivery

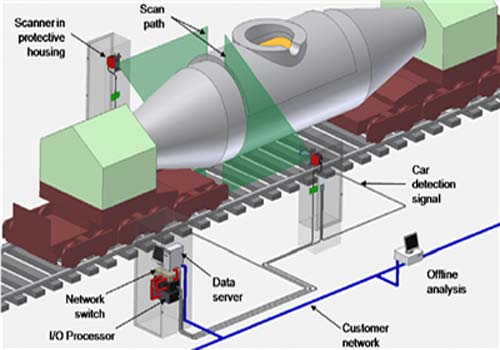

Torpedo ladle, commonly referred to as torpedo ladle, is a device used to contain and transport molten iron.

A torpedo ladle is a device used to contain and transport molten iron. There are two types of open iron water tanks and torpedo iron water tanks. The open iron jug has a ladle for riding; the torpedo ladle is also referred to as a mixed iron car. Torpedo ladle is widely used in foreign large and medium iron and steel enterprises.

The torpedo ladle has the characteristics of large capacity, good thermal insulation performance, low center of gravity and high safety. It can be used as a buffer link between iron and steel interfaces, and plays a role in connecting, matching, coordinating and buffering iron and steel making. It is widely used in enterprises.