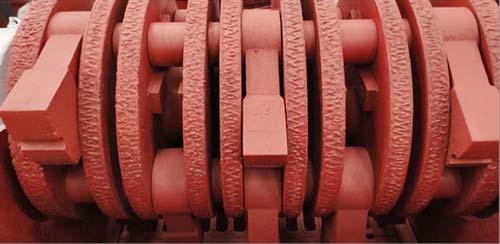

crusher rotor

Crusher Rotor

Crusher machine has been widely used in mining, metallurgy, highway, building materials and other industries. Crusher rotor is a part of the crusher machine and its working performance directly affects the productivity of the crusher machine.

Customized service from professional cement equipment spare parts manufacture

- We use international advanced finite element analysis technology to effectively improve the rotor design.

- Based on the weak parts identified in the stress analysis cloud map of the rotor, we adopt reinforced design and use high-strength and high-quality alloy steel.

- We increase the support flexibility of the bearing seat, reduce the impact load on the bearing, and thereby extend its service life.

- The rotor surface is protected by a tungsten titanium alloy armor design, which greatly reduces stress concentration on the hammer plate and end hammer plate, enhances its strength, effectively prevents fracture problems, and can effectively prevent jamming of the crusher, thus improving the rotor life by more than twice.

- We adopt variable moment of inertia design to effectively improve crushing efficiency, increase crusher output, and reduce fineness by 20-30%.

- The shaft holes around the end plate and hammer plate are thickened on both sides, and extend to the surrounding of the connecting bolt holes. The thickened part is provided with a crescent slot to facilitate the rotation of the hammer head.

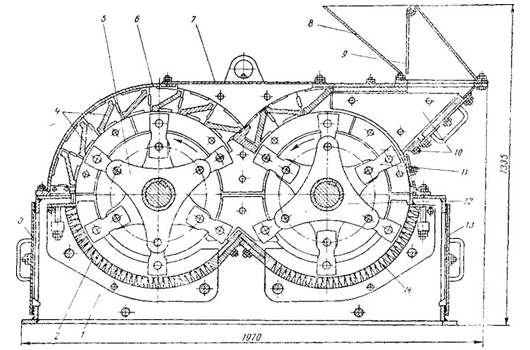

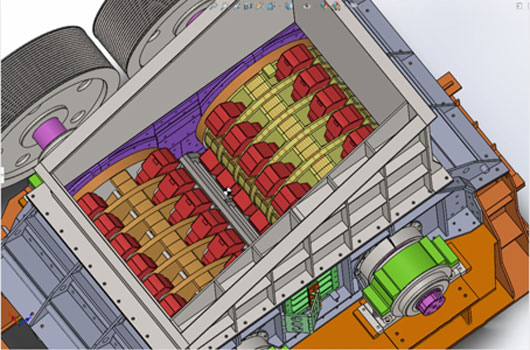

Structure of crusher rotor

Hammer crusher rotor consists of shell, crusher rotor, strike plate, hammer head, bracket, liner and so on.

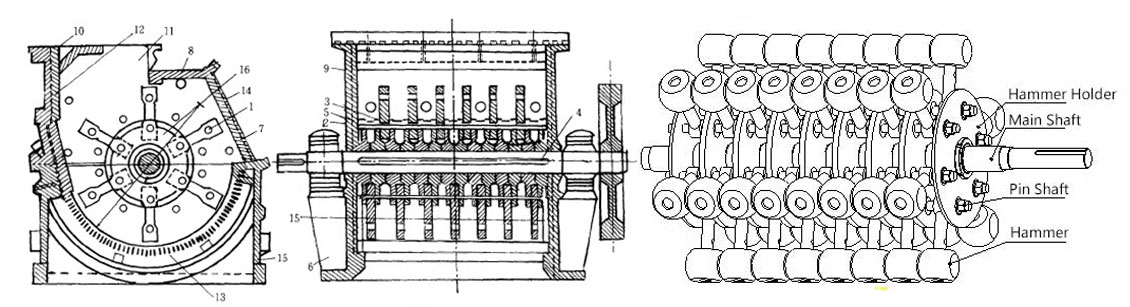

The crusher rotor of the hammer crusher consists of a main shaft, a hammer disc, a pin shaft, and a hammer head. The main shaft is the most important part of the hammer crusher to support the rotor. The weight and impact force of the crusher rotor and the hammer head are all borne by it. Therefore, the material of the main shaft needs to have high toughness and strength. The material of the main shaft is made of high-quality alloys. steel. According to an essay, the rotor peripheral speed of the hammer crusher is currently 18-70m/s.

1. Main shaft

The main shaft is of circular design, the hammer head and the hammer frame are driven to rotate by the rotation of the main shaft. The main function of the main shaft is to bear the weight and impact force from the rotor and the hammer head and ensure stable rotation, which means higher requirements for the material of the main shaft. For some machines, the spindle used for hammer crushing needs to be forged with 35# silicon-manganese-molybdenum-vanadium steel with higher strength and toughness, which is more durable.

2. Hammer frame

The hammer frame is connected to the main shaft and the hammer head, and is not used for crushing materials. However, the hammer frame will still be worn by the impact and friction of the ore during operation. Therefore, the hammer frame is generally selected from high wear-resistant materials. There will be 12 pin holes on the hammer frame, which are divided into two groups. Generally speaking, the newly replaced hammer head is hung on the inner shaft hole of the hammer crusher, and the worn hammer head is hung on the outer shaft hole, so that the new hammer head can be replaced after the hammer head is worn out to saving maintenance costs.

3. Hammer

The hammer head is the part that mainly contacts the ore. The material is crushed by the hammer head's striking and grinding. Therefore, the size, material and shape of the hammer head will affect the crushing effect and crushing efficiency. The higher the weight of the hammer head, the greater the kinetic energy generated during high-speed rotation, and the higher the crushing strength, but the excessive weight may also cause the problem of slow rotation, so the weight is moderate; in addition, the material of the hammer head It is also very important. Generally, high manganese steel casting hammer head can be selected and heat treated, which can make the hammer head have higher wear resistance and impact resistance, and have a longer service life. If it is found to be worn for a long time, it needs to be replaced in time to avoid the broken effect.

4. Flywheel

The flywheel will store a certain kinetic energy during the rotor operation to ensure the rotor can run smoothly, and can reduce the power consumption of the crusher and ensure the crushing effect.

The crusher rotor of the hammer crusher is the part that drives the hammer crusher to work. The quality of the performance will directly affect the production capacity and crushing effect of the hammer crusher. It is necessary to ensure that there is no wear and tear, and the overall operation is stable. Therefore, daily maintenance should also be done during use, and it should be replaced in time after wear.

Advantages of AGICO Cement's crusher rotor

1. Retaining Ring Technology for Prolonged Rotor Service Life

The retaining ring technology prolongs the service life of the rotor. Under the impact of stone, the edge of the rotor and hammer plate of the crusher is easily worn out, and the rotor has to be replaced after wear. In response to this situation, AGICO Cement introduced the retainer technology, which greatly improved the life of the rotor, unscrew the bolt to replace the retainer so that the replacement the crusher rotor is uneccessary.

2. Increased Hammer Disc Diameter and 360-Degree Rotation

The diameter of the hammer disc is increased, and the hammer head can rotate 360 degrees, which reduces the direct impact of the hammer head with the spacer sleeve during the turning process of the hammer head, thus solving the problem that the spacer sleeve of the traditional hammer crusher is easily broken or loosened by the hammer head, and the hammer head falls off and the problem that the hammer shaft is easy to break.

3. Chromium and Manganese Composite Casting

The chromium and manganese composite casting of the hammer head improves the impact resistance of the hammer handle and the performance of the hammer head.

4. Tungsten-Titanium Alloy Full-Armor Protection Design

The tungsten-titanium alloy full-armor protection design on the rotor surface of the crusher reduces the stress concentration of the hammer disc and the end hammer disc, enhances its strength, effectively prevents the problem of breakage, and can effectively prevent the crusher from being stuck and double the life of the crusher rotor.

5. Improved Crusher Output with Variable Rotational Inertia Design

Improve the output of the crusher, adopt the variable rotational inertia design, effectively improve the crushing efficiency, increase the output of the crusher, and reduce the fineness by 20~30%.

Why choose AGICO Cement?

- AGICO Cement has obtained the ISO9001 international quality system certification. The company has established a sound quality management and quality assurance system, which not only employs skilled professionals to conduct quality testing but also has a large number of advanced production equipment and testing instruments, including a 500KG medium frequency furnace, a 2-ton medium frequency furnace, an automatic heat treatment furnace, a universal material testing machine, a Brinell hardness tester, a far-infrared thermometer, an impact testing machine, a wear testing machine, a drop-ball testing machine, a metallographic microscope, and more. This ensures strict quality control of the products.

- AGICO Cement extensively uses design and analysis software such as Nastran, Datran, Deform, and other popular finite element calculation technologies in the mechanical industry to perform strength calculations and optimize design of the crusher structure. In response to the weaknesses of short rotor life, easy damage, low crusher output, and coarse particle size of the single-stage crusher, we have launched a comprehensive improved and strengthened crusher rotor to solve these problems.

- A 5000-ton per day cement production line originally had a rotor lifespan of 2 months. However, after using our company's rotor, the lifespan was extended to 5-6 months, reducing maintenance costs and receiving high praise from the customer.

Our successful cases

.jpg)

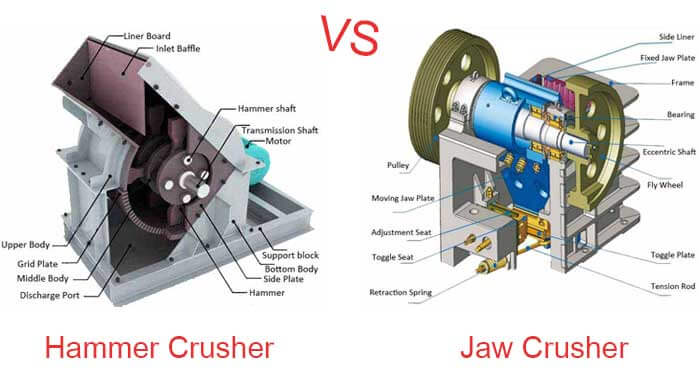

Different between hammer crusher rotor and impact crusher rotor

1. Inside the impact crusher rotor, the crusher rotor runs clockwise, and the plate hammer faces the material from bottom to top, while inside the crusher, the crusher rotor runs counterclockwise, and the hammer head strikes in the direction in which the material falls.

2. The plate hammer of the impact crusher is firmly fixed on the crusher rotor by a mechanical clamping structure, and has a large moment of inertia when rotating with the rotor. Compared with the hammer crusher (the hammer head is suspended), the rotor of the impact crusher has greater momentum, which is suitable for crushing harder materials and consumes less energy.

3. The hammer head of Impact crusher is rigidly connected with the crusher rotor, which has a milling effect before the material is discharged; while the hammer head of the hammer crusher hangs freely on the crusher rotor. When encountering materials that are difficult to crush, it must be turned to avoid it Protect the hammer from damage, but not break.

FAQs about crusher rotor

- What is a crusher rotor?

A crusher rotor is a rotating component within a crushing machine that is responsible for breaking down large rocks and other materials into smaller pieces. It typically consists of a central shaft, several blades or hammers, and various wear-resistant components. - How does a crusher rotor work?

When a crusher rotor is spinning, the blades or hammers attached to it strike and break down large rocks and other materials that are fed into the machine. The speed and force of the rotor can be adjusted to control the size and shape of the crushed material. - What materials are crusher rotors typically made of?

Crusher rotors are typically made of high-strength steel or cast iron, depending on the specific application and requirements. They may also feature specialized wear-resistant coatings or inserts to extend their lifespan. - What are some common problems with crusher rotors?

Common problems with crusher rotors include excessive wear, damage or cracking of the blades or hammers, and unbalanced rotation. These issues can be caused by a variety of factors, including improper maintenance, excessive use, and material buildup. - How can crusher rotor problems be prevented or addressed?

To prevent or address crusher rotor problems, it is important to follow proper maintenance procedures, including regular inspections and cleaning. Replacement blades or hammers should be used when necessary, and the rotor should be properly balanced to ensure smooth and efficient operation. Additionally, operators should be trained to recognize and address any issues as soon as they arise. - What is the role of wear-resistant components in a crusher rotor?

Wear-resistant components, such as plates or inserts, are used to protect the rotor from damage and extend its lifespan. These components are typically made of materials that are harder and more durable than the surrounding metal, and they can be replaced when they become worn or damaged. - What factors affect the performance of a crusher rotor?

Several factors can affect the performance of a crusher rotor, including the speed and torque of the motor driving the rotor, the size and shape of the blades or hammers, the material being crushed, and the moisture content of the feed material.

- How can crusher rotor problems be prevented or addressed?

To prevent or address crusher rotor problems, it is important to follow proper maintenance procedures, including regular inspections and cleaning. Replacement blades or hammers should be used when necessary, and the rotor should be properly balanced to ensure smooth and efficient operation. Additionally, operators should be trained to recognize and address any issues as soon as they arise. - What is the role of wear-resistant components in a crusher rotor?

Wear-resistant components, such as plates or inserts, are used to protect the rotor from damage and extend its lifespan. These components are typically made of materials that are harder and more durable than the surrounding metal, and they can be replaced when they become worn or damaged. - What factors affect the performance of a crusher rotor?

Several factors can affect the performance of a crusher rotor, including the speed and torque of the motor driving the rotor, the size and shape of the blades or hammers, the material being crushed, and the moisture content of the feed material. - How can the efficiency of a crusher rotor be improved?

To improve the efficiency of a crusher rotor, operators can adjust the speed and torque of the motor to optimize the crushing process, use properly sized blades or hammers for the material being crushed, and ensure that the rotor is properly balanced to reduce vibration and wear. - What are some safety considerations when working with crusher rotors?

Working with crusher rotors can be dangerous, as the blades or hammers can cause serious injuries if not handled properly. Operators should wear appropriate personal protective equipment, such as gloves and eye protection, and follow all recommended safety procedures when working on or around crusher rotors. - How can I choose the right crusher rotor for my application?

Choosing the right crusher rotor depends on several factors, including the size and hardness of the material being crushed, the required output size and shape, and the specific requirements of your crushing operation. Consulting with a knowledgeable supplier or manufacturer can help ensure that you choose the right rotor for your needs.

Video of how to renovate crusher rotor