Power Transformer

Introduction of power transformer of industrial dust collector

The high-voltage power transfomer of an electric dust collector is the core device of the electric dust collector. Its main function is to provide high-voltage electricity to the electrodes of the electric dust collector, as well as the electrical energy required for charging dust and collecting dust. The operational performance of the electric dust collector is directly influenced by the quality of the power supply. The high-voltage power transfomer is a closed-loop control system that uses voltage and current as control parameters. It includes high-voltage silicon rectifiers, high-impedance transformers, the main control regulator, and sensors for the control system.

The high-voltage silicon power transfomer consists of two major components: the boosting transformer and the rectifier. It has several advantages, such as good heat dissipation, reliable operational performance, and a well-designed structure with good insulation properties. The high-voltage silicon power transfomer can be classified into high-impedance and low-impedance transformers based on the impedance value. The low-impedance transformer has a very small impedance value and requires coordination with reactors for proper usage. The high-impedance transformer, based on the design of the low-impedance transformer, changes the design position of the inductance in the main circuit, internal to the transformer. This increases the impedance, eliminating the need for a flat-wave reactor. However, the voltage on the impedance of the transformer becomes higher, resulting in larger volume and losses. During operation, it releases a considerable amount of heat, requiring effective heat dissipation conditions.

The electric dust collector can be divided into the main body and the power supply system, with the power supply system further divided into high-voltage and low-voltage systems. The high-voltage power supply system converts single-phase low-voltage AC (380V) into high-voltage DC (usually 60-72kV in China) through rectifiers. Initially, synchronous mechanical rectifiers were used, followed by the invention of electronic tube rectifiers in the 1960s. However, electronic tube rectifiers did not replace synchronous mechanical rectifiers. Solid selenium rectifiers were introduced, replaced four years later by silicon rectifiers. Silicon rectifiers have low forward impedance, no noise, long service life, and high rectification efficiency, making them the preferred choice to date. To achieve high dust removal efficiency, the high-voltage power supply must be controlled through a low-voltage system to achieve optimal high-voltage values.

How does the power transformer of industrial dust collector work

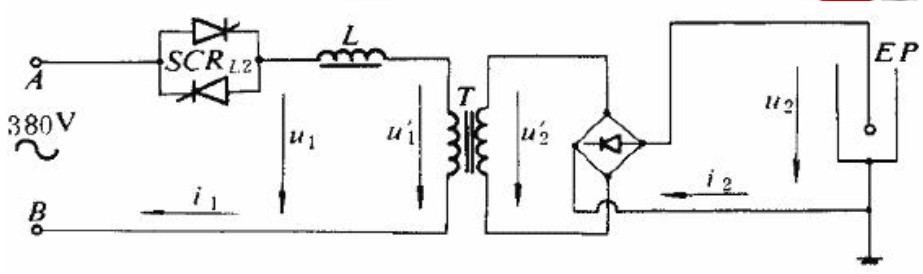

The high-voltage power supply system uses a controllable silicon voltage regulation device. To obtain the basis for adjusting the controllable silicon conduction angle, the control system reads the data saved from the previous shutdown as well as some original settings as parameters during operation. The current and voltage signals sampled by the transformer's secondary and primary are filtered and provided to the operational amplifier. After amplification, they are sent to the input of the A/D converter. Once converted into corresponding digital and analog signals, they are sent to the controller. Through data analysis and judgment of the operational status of the electric field, the control system adjusts the conduction angle of the controllable silicon on the primary side of the main circuit, determining the triggering conduction angle of the controllable silicon. As the triggering angle of the controllable silicon is calculated from the positive half-cycle of the zero crossing point, a synchronous detection signal is simultaneously provided. Starting from synchronization, it finally triggers the controllable silicon through the triggering pulse transformer. The high voltage obtained after the transformer boosts and rectifies is applied to the electrodes, generating an electric field, allowing the system to operate in a set control mode. The completion of one cycle of operation is indicated by the current decreasing to zero, and the controllable silicon automatically closes.

Why choose AGICO Cement?

Our new generation high-frequency high-voltage power supply for electric dust removal, represents a significant leap in core technology compared to traditional power supplies. It is a product of technological innovation and offers substantial energy savings and efficiency improvements for electric dust removal systems.

The electric dust removal high-frequency power supply boasts features such as lightweight and compact design, high average voltage, low DC ripple, symmetrical three-phase load, high power factor, and conversion efficiency. In comparison to conventional power sources operating at line frequency, the average voltage can be increased by 10-30KV. It exhibits superior power supply characteristics, resulting in noticeable energy-saving effects and a significant enhancement in dust removal efficiency.

This product incorporates advanced control concepts, utilizing highly reliable main switching components. With fully digitalized control and multiple control modes, it facilitates easy centralized management. It represents a state-of-the-art solution for electric dust removal, providing not only energy efficiency but also improved dust removal performance.