cage rotor

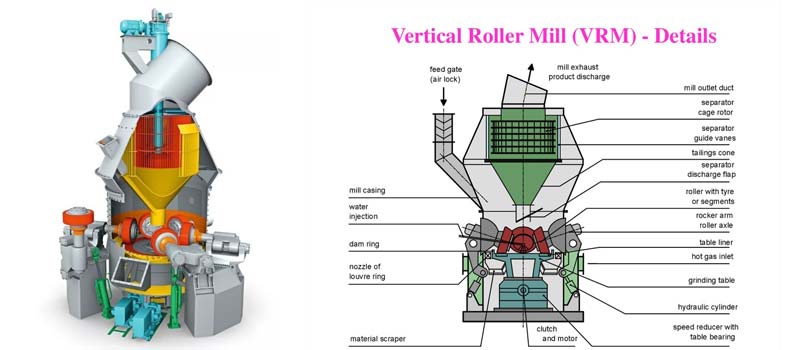

The working principle of the vertical mill is that the motor drives the grinding disc to rotate through the reducer, the material falls into the middle of the grinding disc from the feed port through the air lock feeder, and the hot air enters the mill from the air inlet. With the rotation of the grinding disc, the material moves to the edge of the grinding disc under the action of centrifugal force, and is crushed by the grinding roller when passing through the annular groove on the grinding disc. The particles fall directly to the grinding disc for re-grinding. When the material in the airflow passes through the upper separator, under the action of the cage rotor, the coarse powder falls from the cone bucket to the grinding disc for re-grinding. The dust collection device is the product. The material containing moisture is dried during the contact with the hot air. By adjusting the temperature of the hot air, it can meet the requirements of materials with different humidity and achieve the required product moisture. By adjusting the separator, the required thickness of different products can be achieved.

Vertical mills are mostly used in raw meal preparation systems in cement production. The materials ground and dried by the vertical mill enter the separator from the lower part together with the airflow, and the air guide vanes of the separator make the dust and air form a tangential flow. The rotation direction of the cage rotor is the same as the vortex direction of the wind guide blades. At the gap between the guide vanes and the cage rotor vanes, a centrifugal force space is formed, so that the dust/air can be separated.

Large particles of material are thrown to the outside, fall down by gravity, and after leaving the gap, are collected and returned to the grinding table for regrinding. The finished material leaves the separator together with the air through the outlet pipe of the separator.

The fineness of the finished material depends on the adjustment of the seperator roto speed. If the speed of the rotor is increased, the grinding material will be finer; on the contrary, if the speed of the cage rotor is reduced, the particles of the material will become coarser, and the products with qualified fineness must be adjusted gradually during the debugging of the mill.