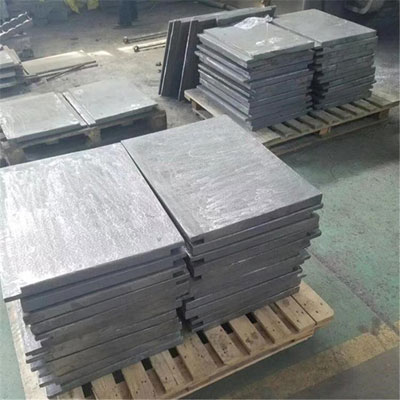

Cooler Grate Plates

Centrifugal casting, sand casting, disappearing mold casting and other processes, the mold size is high, the material organization is uniform, the performance is stable, especially the shaped tube can be done as a whole casting.

AGICO Cement's main products:

All kinds of casting steel plate, steel pipe, shaped castings according to the drawing processing heat-resistant steel, heat-strengthened steel, high-temperature-resistant furnace pipe, high-temperature-resistant alloy steel, alloy steel, wear-resistant steel, heat treatment accessories

Main features:

High temperature loss, high sulfur resistance, impact resistance easy to cut, can be welded and so on. Compared with similar heat-resistant steel products can improve the service life of 1-3 times, and the cost of similar materials 5% -15%, in a high-temperature environment of 1000-1300 ℃ can be used continuously.

Cooler grate plates

Cooler grate plates are a kind of element inside the grate cooler, also known as heat exchanger plates, which are flat plate-like components made of metal materials. In the grate cooler, hot air and cooling water pass through the cooler grate plates for heat exchange and cooling.

The role of cooler grate plates

Cooler grate plates is a very important part of the grate cooler, has the following roles:

1. Realize the transfer of heat

Through the surface plating or galvanization, cooler grate plates make the hot air and cooling water isolated from each other, and at the same time realize the heat transfer. Such a way of heat transfer, can maximize the use of cooling water cooling capacity, effective cooling grate cooler equipment and machinery.

2. Ensure the normal operation of the grate cooler

Cooler grate plates is a very key component in grate cooler, its cooling effect directly determines the performance and operating efficiency of the grate cooler. In other words, if the cooler grate plates are not cooled well, the grate cooler can not run normally. Therefore, cooler grate plates are an important guarantee to ensure the normal operation of the grate cooler.

Materials you can choose-- we provide customized service

| Traditional International Materials (500~800°C) | Traditional International Materials (800~1000°C) | Super Heat-Resistant Steel (1000~1100°C) | Super Heat-Resistant Steel (1100~1250°C) | Super Heat-Resistant Steel (1250~1400°C) |

Z640CrmnMoNi Z640Cr5Mo Z60r9Si2 Z60r13Mo | Z610Cr18Ni9Ti Z630Cr26Ni5 Z630Cr20Ni10 Z635Cr26Ni12Si | Z640Cr28Ni16 Z640Cr25Ni20Si2 Z635Cr30Ni20 Z635Cr24Ni18Si2 | Z635Cr25Ni35 Z640Cr35Ni35 HXD-ZG-01 HXD-ZG-05 | Z640Cr28Ni48W5Si2 Z635Cr20Ni80 HXD-ZG-05 HXD-ZG-06 |

Why choose AGICO Cement?

Strong strength, advanced brand in the industry

- Gathering a large number of strategic innovation, representing the industry's national level of maturity of the outstanding scientific research team .

- with well-known enterprise suppliers, to undertake thousands of institutional investment.

- China Quality Management System Certification Center certified "National High-tech Enterprises".

National certification, preferred quality

- The products have passed ISO9001 quality system certification and international quality system certification.

- 8 production lines to control the manufacturing process, high product yield, stable operation.

- Advanced testing equipment as products qualified products

Good technology, high-end production

- With more than 10 years of experience in software and hardware production technology.

- International high-tech enterprises, with a number of inventions and utility model patents.

- Products identified by the national ministry for environmental protection enterprises, the level of technology is trustworthy.

Mature team, perfect service

- More than 500 senior professional team, free of charge for you to customize the acquisition of solutions.

- The company sends technicians to guide the installation of equipment 365 days 24 hours after-sales service.

Classification of Cooler Grate Plates

Cooler grate plates can be classified into different types such as stainless steel cooler grate plates, copper cooler grate plates and aluminum cooler grate plates according to the different materials used to make them.

1. Stainless steel cooler grate plates

Stainless steel cooler grate plates are usually used in food, agriculture, chemical and other industries, because stainless steel has anti-corrosion, acid and alkali resistance, high temperature resistance, and at the same time, the surface is clean and pollution-free, which can ensure product quality.

2. Copper cooler grate plates

Copper cooler grate plates are generally used in building materials, water heaters, swimming pools and other occasions, because copper has good thermal conductivity and good strength, but also can inhibit the growth of bacteria.

3. Aluminum cooler grate plates

Aluminum cooler grate plates are usually used in air conditioning, automotive, stamping, etc. because aluminum has light weight, high strength, good thermal conductivity and corrosion resistance.

In short, different types of cooler grate plates have their application advantages in different fields. Choosing the right cooler grate plates can not only reduce the cost, but also improve the efficiency and durability of the grate cooler.

Properties and Applications of General-Purpose Heat-Resistant Steel & Alloy Castings

| Grade | Max Temp. | Key Properties | Applications | Chemical Composition (%) | Mechanical Properties (Annealed) |

|---|---|---|---|---|---|

| ZG40Cr9Si2 | 800°C | Low high-temp strength, oxidation resistance up to 800°C. Long-term load-bearing parts should operate below 700°C. | Crucibles, furnace doors, base plates. | C: 0.35–0.50; Mn: ≤0.70; Si: 2.00–3.00; Cr: 8.00–10.00; P: ≤0.035; S: ≤0.030 | Tensile strength: ≥550 MPa; Yield strength: —; Elongation: — |

| ZG35Cr24Ni7SiN | 1100°C | Excellent oxidation resistance. | Furnace linings, fan blades, hot rails, base plates, cement/glass mixers. | C: 0.30–0.40; Mn: 0.80–1.50; Si: 1.30–2.00; Cr: 23.0–25.0; Ni: 7.00–8.50; N: 0.20–0.28; P: ≤0.04; S: ≤0.03 | Tensile strength: ≥540 MPa; Yield strength: ≥340 MPa; Elongation: ≥12% |

| ZG30Cr18Mn12Si2N | 950°C | Good high-temp strength & thermal fatigue resistance. | Furnace walls, conveyer rails, supports, hangers. | C: 0.26–0.36; Mn: 11.0–13.0; Si: 1.60–2.40; Cr: 17.0–20.0; N: 0.22–0.28; P: ≤0.06; S: ≤0.04 | Tensile strength: ≥490 MPa; Yield strength: —; Elongation: — |

| ZG30Cr26Ni15 | 1050°C | Load-bearing up to 650°C (light load: 1050°C). Prone to σ-phase at 650–870°C. | Ore sintering furnaces, high-melt environments without stringent strength requirements. | C: 0.20–0.40; Mn: ≤1.00; Si: ≤2.00; Cr: 24.0–28.0; Ni: 14.0–16.0; Mo: ≤0.50; P: ≤0.04; S: ≤0.04 | Tensile strength: ≥590 MPa; Yield strength: —; Elongation: — |