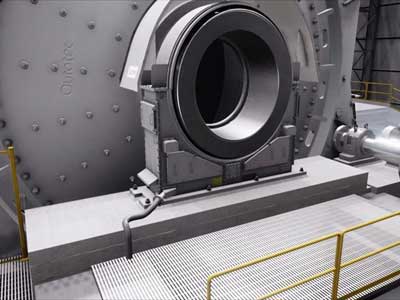

bearing housing

Material: Cast steel

Unit Weight: 3-20 Tons

Type: Large bearing housing

Application: Ball mill, rotary kiln, rolling mill, vertical mill

Customizable: yes

Introduction

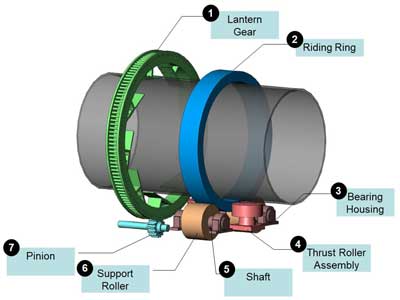

The bearing housing is used to support the bearing and fix the outer ring of the bearing to only let the inner ring rotate and the outer ring remains stationary so that the bearing always consistent with the direction of the transmission (such as the direction of motor operation) and maintain balance. The concept of bearing housing is the assembly of the bearing and the box body which is convenient for application. It has the characteristics of compact structure, sensitive rotation, and convenient device maintenance. Where there is a bearing, there must be a support point. The inner support point of the bearing is the shaft, and the outer support is the so-called bearing housing/bearing chock.

Since a bearing can choose different bearing housing, and a bearing housing can choose different types of bearings at the same time, there are many varieties of bearing housings. AGICO can provide customized service for customers to produce various high-quality bearing housing of different shape and material based on customers' drawing and requirements.

Advantages of AGICO's bearing chock

The bearing chock has to endure with long-time operation in the environment of low speed and heavy load and accompanied with shock, so the reliability of the components is particularly important. Thus, good quality must be guaranteed.

In order to achieve the purpose of stable and high production, AGICO's bearing chock meets the following requirements:

1. Long service life. AGICO applies ZG35 and ZG45 steel which have the feature of strong hardness, high wear resistance, strong bearing capacity. It can work continuously for a long time with good stability and long service life.

2. The matching of the inner and outer rings of the bearing requires that the bearing not only be able to move axially in the bearing seat (to adapt to the thermal expansion and contraction of the cylinder), but also be able to transmit the torsional moment, and at the same time, it must be able to compensate the dynamic (static) load of the cylinder. The journal declination angle produced by the lower deformation;

3.The structure of the bearing chock should be easy to install, lubricate, clean, inspect and maintain.

4.Low temperature to save the electricity cost. The bearing chock is lubricated with thin lubricating oil to reduce the friction coefficient of the bearing to a relatively low value so that the power saving effect will achieve to ideal value and the normal operation temperature of the bearing is much lower than that of the dry oil lubricated bearing and extend the service life of bearing.

5.Oil level observation scale line is set beneath the bearing chock to let the operator see the oil level at any time during production, which can replenish the oil in time and prevent poor lubrication due to lack of oil, and avoid the occurrence of bearing damage accidents.