Enhance Your Milling Process with Essential Ball Mill Parts

The ball mill machine, as a common grinding equipment, is usually equipped with various components to ensure its smooth operation and efficient grinding. The following are the common components of a ball mill machine:

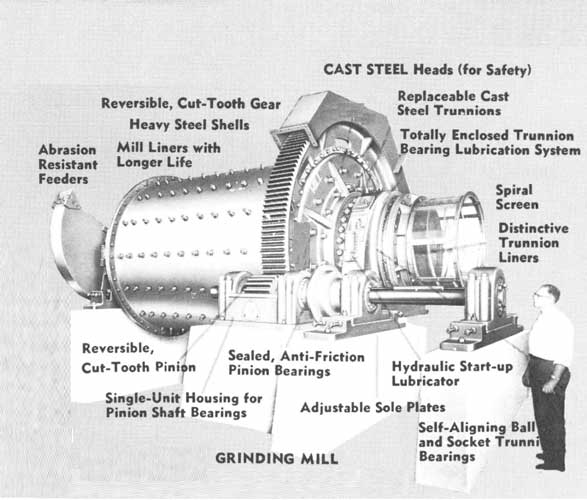

Mill liner: The mill liner is a protective layer that covers the inner wall of the ball mill cylinder. It is typically made of wear-resistant and corrosion-resistant materials such as high-chromium alloy steel, rubber, or polyurethane. Its purpose is to protect the mill cylinder from the wear and chemical corrosion caused by grinding balls.

Grinding balls: Grinding balls are the media used in the ball mill for grinding materials. They are usually made of steel or ceramic and their size and material selection depend on the hardness of the materials and grinding requirements.

Gears and transmission device: Gears and the transmission device are used to transmit power from the motor and transfer the rotational speed to the mill cylinder. They typically include gears, couplings, motors, and reducers.

Feed device: The feed device is used to uniformly feed materials into the mill cylinder of the ball mill. Common feed devices include screw conveyors, vibrating feeders, and feed hoppers.

Discharge device: The discharge device is used to discharge the ground materials from the ball mill. Common discharge devices come in the form of hollow shafts, hollow mill heads, and cylinder covers. By opening the discharge device, the materials can be smoothly discharged from the ball mill.

Cooling system: During the ball milling process, a significant amount of heat is generated. To prevent the equipment from overheating, ball mill machines are usually equipped with cooling systems. Common cooling systems include cooling water jackets or air cooling systems, which help lower the temperature of the mill cylinder and other heat-sensitive components.

Discharge system: The discharge system is used to direct the discharged materials into the next processing stage or collector. It typically includes conveyors, screw conveyors, or pipelines.

Control system: The control system of the ball mill machine is used to monitor and regulate the operation of the equipment. It usually includes electrical control cabinets, instruments, and automation devices, allowing adjustment and control of parameters such as feed rate, mill cylinder speed, and discharge rate.

Lubrication system: The lubrication system of the ball mill machine is used to provide lubrication and cooling to critical components, reducing friction and wear. It includes lubricating oil tanks, lubricating oil pumps, oil pipes, and lubrication points.

Grinding media supply system: To maintain a proper supply of grinding media (balls) inside the mill cylinder and stabilize their size, ball mill machines are typically equipped with a grinding media supply system. This system consists of supply devices, conveying pipes, and metering devices.

Exhaust system: During the ball milling process, dust and exhaust gases are generated. To purify the air and maintain a good working environment, ball mill machines are usually equipped with an exhaust system. This system includes fans, ducts, and dust removal devices.

Vibrating screen: The vibrating screen is used to classify and screen the ground mineral materials, controlling the particle size distribution of the ore. It is typically located near the discharge port of the ball mill, and the separation of different particle sizes is achieved through the screen's aperture size and vibration frequency.

Cleaning device: To maintain the cleanliness of the interior of the ball mill and avoid cross-contamination of materials, ball mill machines are typically equipped with a cleaning device. The cleaning device can be a spraying device, cleaning water pipes, or cleaning tanks, used to clean the mill cylinder and other components.

Inspection doors and observation holes: Ball mill machines are usually equipped with inspection doors and observation holes to facilitate equipment maintenance and inspection. Inspection doors are typically located on the side or top of the mill cylinder, allowing convenient equipment repairs and replacement of parts.

These components together constitute the complete equipment of a ball mill machine, achieving fine grinding and processing of materials through their respective functions and collaborative effects. The specific component configuration and specifications may vary depending on different models and applications, but the above description covers the common components of a ball mill machine.